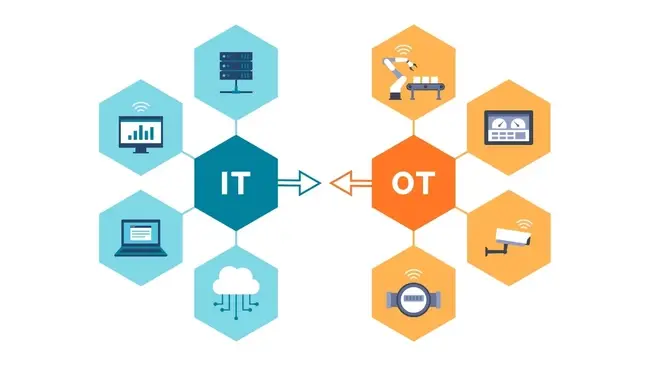

As more and more organisations digitize their operations and connect OT devices to the internet, the distinction between information technology (IT) and operational technology (OT) is becoming increasingly blurred.

This convergence is creating new challenges and opportunities, requiring a more integrated approach to managing these types of technologies, as well as increased security to keep both types secure.

But how exactly are IT and OT systems different today, and where do they interact? This article delves into information technology (IT) and Operational Technology (OT), exploring the differences that separate IT and OT systems and the similarities that bring them together.

What is IT?

Information Technology (IT) is technology that uses computers, networks, software, and other digital tools to manage and transmit data. IT systems are defined by their programmable capabilities. Unlike technologies designed to perform specific tasks, they can be adjusted, enhanced and re-programmed to meet different needs.

Although IT is often associated with computers, devices like smartphones, servers, IoT devices, and tablets are also all a part of IT infrastructure. That's because they all have the same hardware and network work equipment, as well as software including applications, operating systems, and virtualisation tools.

Because IT is closely tied to network access, companies need to make sure all data is secure and that any potential risks are continuously identified and mitigated.

IT professionals handle tasks such as software development, network administration, and database management, contributing to the overall digital infrastructure of an organisation.

Access to IT systems and connected devices is typically less restricted than OT devices since many if not all employees at an organisation may have access to a network.

What is OT?

Operational technology (OT) is any technology that monitors and controls specific devices and processes within industrial workflows. Unlike IT which primarily deals with digital systems, OT focuses on the management of real-world processes, often integrating with IT to create comprehensive systems for efficient operations.

OT systems work in tandem to manage everything from assembly lines in factories to power distribution grids. These systems encompass a wide range of technologies, such as industrial control systems (ICS), supervisory control and data acquisition (SCADA) systems, programmable logic controllers (PLCs), and sensors. Their goal is to enhance operational efficiency, ensure safety, and improve decision-making through the real-time monitoring and control of physical processes.

One of the biggest challenges for teams managing OT systems is therefore to reduce downtime. When these systems are pushed offline, it can devastate a business' operations, leaving them struggling to continue running. They therefore need to invest big in securing these systems, often turning to OT security vendors to protect systems from malicious actors.

When IoT Rewrites Inventory

See how connected devices shift inventory from manual counts to always-on visibility, cutting discrepancies and stabilizing supply chains.

IT vs OT: What’s the Difference?

The main difference between IT and OT is that OT systems control the physical operations of a business and the machines used to carry them out, while IT devices manage the flow of company data. IT acts as the digital backbone of an organisation but OT is the system that makes their physical machinery work.

A traditionally good analogy to understand this difference is that IT represents the office in a company while OT represents the factory floor. IT also traditionally refers to software, while OT generally encompasses hardware.

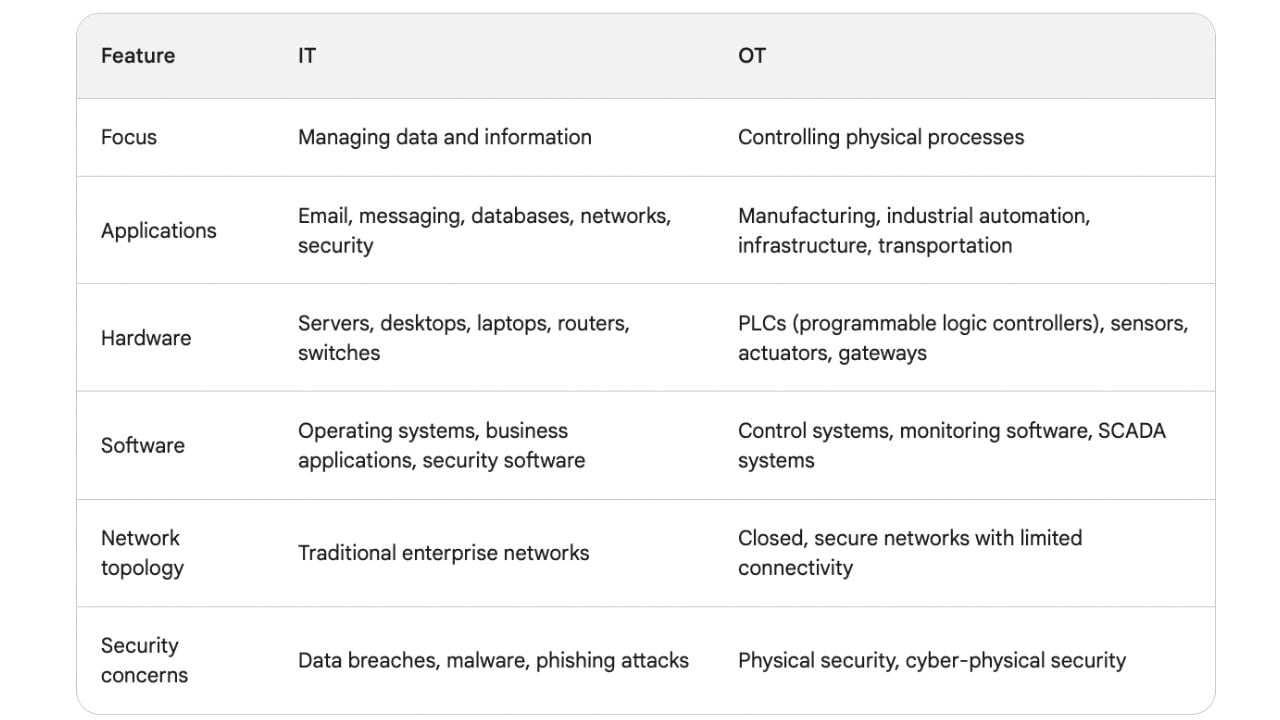

There are also several core differences between IT and OT that separate the two technologies. These include:

- Scope and Focus

- IT deals with digital systems, networks, software, and data management. They focus on information processing, storage, and security for business operations, data analysis, and communication.

- OT deals with the physical processes and machinery involved in industries like manufacturing, energy, transportation, and more. They focus on real-time control, monitoring, and optimisation of these processes.

- Goals

- IT systems aim to ensure data availability, integrity, confidentiality, and the efficient flow of data across the organisation.

- OT systems aims to optimise operational efficiency, maintain safety, reduce downtime, and manage physical processes effectively.

- Security Concerns

- IT security focuses on protecting digital assets, networks, and data from cyber threats like hacking, malware, and data breaches.

- OT security focuses on safeguarding physical processes from cyber threats, as a breach in a system could lead to physical damage, accidents, or disruptions.

- Network Characteristics

- IT networks are usually standardised, using Ethernet, TCP/IP, and other common protocols for data communication.

- OT networks might use specialized protocols and technologies tailored to the requirements of industrial equipment and processes.

- Lifecycles

Inside 2024’s Edge Stack Leaders

Which hardware, network and cloud platforms are defining edge architectures and where they fit in enterprise roadmaps.

- IT systems often experience frequent updates and changes due to rapid advancements in software and technology.

- OT systems tend to have longer lifecycles due to the need for stability and reliability. Upgrades can be more complex and carefully managed to avoid disrupting critical processes.

Here is a table summarising the difference between IT and OT:

Where do IT and OT intersect?

As more and more organizations connect OT devices to the internet, the distinction between IT and OT is blurring. This convergence is creating new challenges and opportunities, requiring a more integrated approach to managing both IT and OT systems.

In the past, OT devices were kept away from online networks, and could only be accessed by a selected few employees. But as companies embrace the cloud and embark on digital transformation initiatives, many of these systems are now managed by IT.

This convergence of OT and IT, often referred to as the Industrial Internet of Things (IIoT) is transforming industries by enabling unprecedented levels of automation, data-driven insights, and predictive maintenance. At the same time, however, it is also bringing a host of new challenges.

Once OT systems are connected to the internet, they become vulnerable to a pandora's box of new cyber threats, leaving critical business infrastructure vulnerable to breaches. Many OT systems use older technologies that might lack modern security defences, and integrating these legacy systems with IT networks can expose them to vulnerabilities that are difficult to fix.

The interconnected nature of IT and OT can also extend the attack surface s to third-party suppliers and partners, increasing the risk of supply chain attacks. Companies might also have different security standards and decision criteria to address this threat which can result in friction between the teams.

Despite the risks, the convergence of IT and OT is inevitable. The proper implementation and management of these technologies will remain crucial in driving the evolution of industries towards a more connected and efficient future.

Comments ( 0 )