Modern enterprises run on configuration. Products ship in hundreds of variants, software is released continuously, and infrastructure changes weekly. Without a coherent way to define, control, and trace these moving parts, errors multiply and costs rise.

A Configuration Lifecycle Management approach solves that gap by creating a shared configuration truth that spans engineering, commercial, manufacturing, service, and IT.

What Configuration Lifecycle Management is

First coined by Configit, Configuration Lifecycle Management (CLM) approaches manage all product configuration definitions and resulting configurations across business processes throughout a product’s lifecycle. It aligns configuration data and rules so every downstream team works from consistent, current information.

CLM strategies are often implemented alongside Product Lifecycle Management (PLM) and Product Data Management (PDM), but its focus is distinct. Where PLM governs product data broadly, CLM concentrates on product configuration logic, variability, and the propagation of that logic into systems like CPQ, ERP, MES, CRM, and service tools.

Done well, CLM closes the loop between design intent and what is sold, built, delivered, and maintained. For infrastructure leaders, the same principles apply to software-defined estates. Network and platform configurations evolve across planning, deployment, operations, and retirement.

Treating these as a managed lifecycle, not one-off changes, improves reliability and auditability.

Why CLM Matters For Enterprise Leaders

Enterprises that rely on configured products and software face a common set of risks:

- Fragmented rules living in spreadsheets and point tools.

- Divergence between what engineering designs, what sales quotes, what factories build, and what service maintains.

- Limited traceability when a defect or compliance issue appears in the field.

CLM tackles these by establishing a shared source of configuration truth, enforcing rule-based variability, and enabling closed-loop change across the lifecycle. In practice, that reduces quoting errors, build stops, and service misdiagnoses while speeding up change.

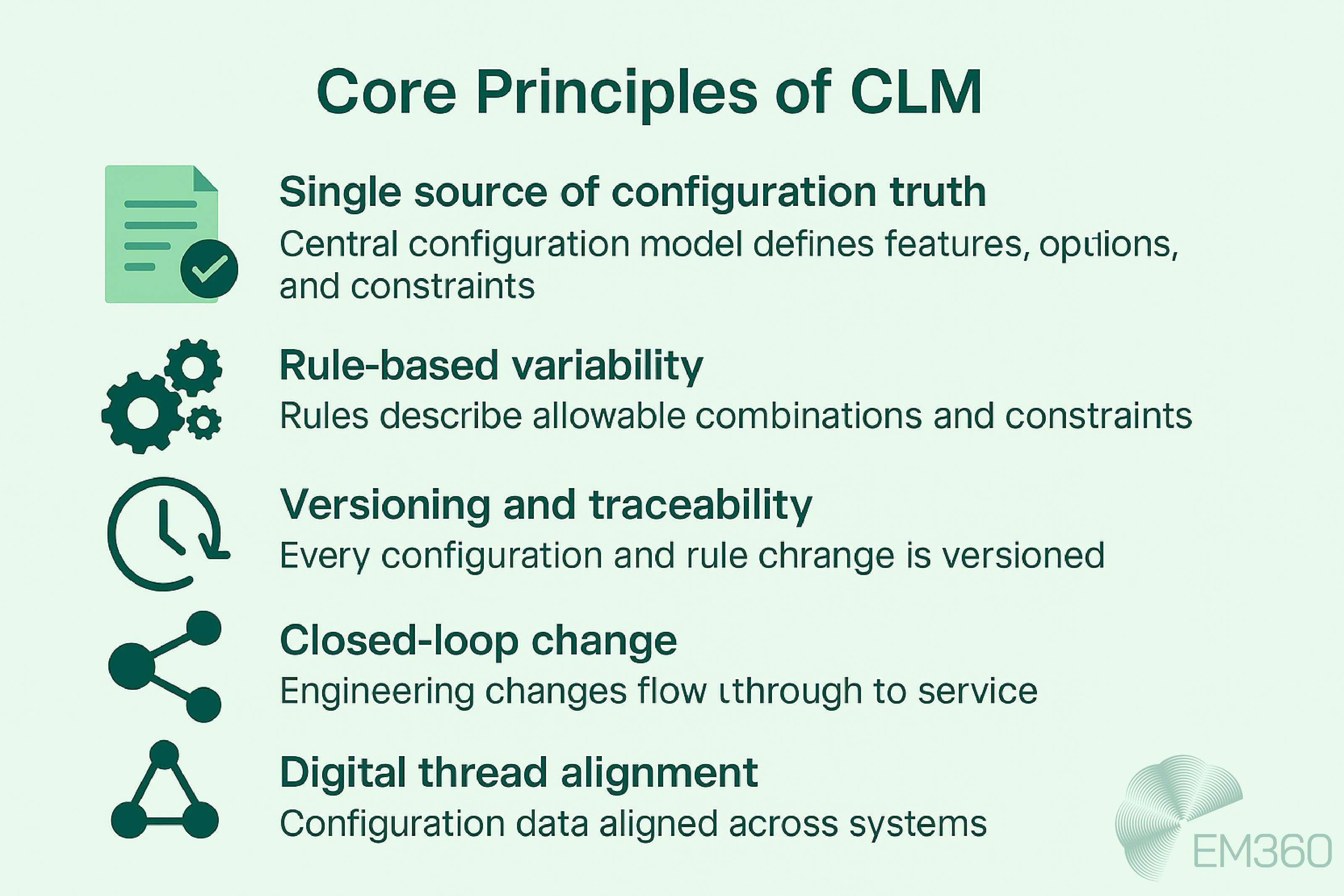

Core Principles Of CLM

A Configuration Lifecycle Management approach works when a few core practices are introduced early, then reinforced in process, data, and tooling. The aim is simple: one configuration truth that every team can trust, versioned and governed from design to operations.

Shared source of configuration truth

Create a central configuration model that defines features, options, constraints, and compatibility. This is the authoritative source, not a reference that gets copied into spreadsheets or rebuilt in each system. The model feeds the tools your teams already use, such as Product Lifecycle Management (PLM), Configure Price Quote (CPQ), Enterprise Resource Planning (ERP), Manufacturing Execution Systems (MES), and IT Service Management (ITSM).

In practice, this stops divergence. If engineering retires an option, sales cannot quote it, manufacturing will not plan it, and service will not order parts for it. For infrastructure teams, the same model drives golden builds for servers, networks, and clusters, so the configuration you design is the configuration that gets deployed and supported.

Rule-based variability

As products and platforms gain options, hard-coded combinations become unmanageable. CLM replaces that with declarative rules that explain what is allowed and why. These rules capture dependencies, exclusions, regional or regulatory limits, and performance caps.

Because rules are maintained centrally, the impact of change is controlled. Introduce a new option, adjust a dependency, or add a compliance constraint, then publish to every consumer. For IT estates, rules can express policy constraints, for example encryption required for specific data classes, minimum firmware versions, or network segmentation rules that must be enforced at build time.

Versioning and traceability

Every meaningful item in CLM must be versioned: rules, feature definitions, option codes, and the configurations derived from them. Versioning enables full traceability. You can reconstruct the exact configuration that was sold, built, shipped, deployed, or maintained for a named customer on a specific date, then link it to the rule set in force at that time.

Why Observability Now Matters

How telemetry, tracing and real-time insight turn sprawling microservices estates into manageable, high-performing infrastructure portfolios.

This makes audits straightforward and incident response faster. If a defect or vulnerability is discovered, you know who is affected, which options triggered exposure, and which corrective configuration is valid. For infrastructure leaders, it means clear lineage from approved templates to live environments, with evidence for change boards and regulators — the same principle that underpins versioning and change logging in enterprise data pipelines.

Closed-loop change

CLM is not a one-way push from engineering to the rest of the business. It is a loop. Changes originate in design, flow into commercial tooling, then into manufacturing or deployment, and finally into service. Feedback travels the other way. Production yield issues, field failures, and service workarounds inform updates to rules and options.

For IT, the loop connects design, build, run, and improve. Telemetry, incident trends, and post-change checks feed back into the central configuration model. Over time, the rule set reflects what actually works at scale, not just what was intended.

Digital thread alignment

The digital thread connects data across the lifecycle so that decisions are made with full context. The CLM approach strengthens that thread by aligning configuration semantics across systems such as Model-Based Systems Engineering (MBSE), PLM, CPQ, ERP, MES, service tools, and ITSM.

Rather than mapping one-off fields between platforms, CLM keeps shared identifiers, option codes, and rule meanings consistent. The result is fewer translation errors, easier impact analysis, and faster decision cycles. If a design option changes, the same option code and rule logic follow it through quoting, planning, assembly or deployment, and service, so every team is speaking the same configuration language.

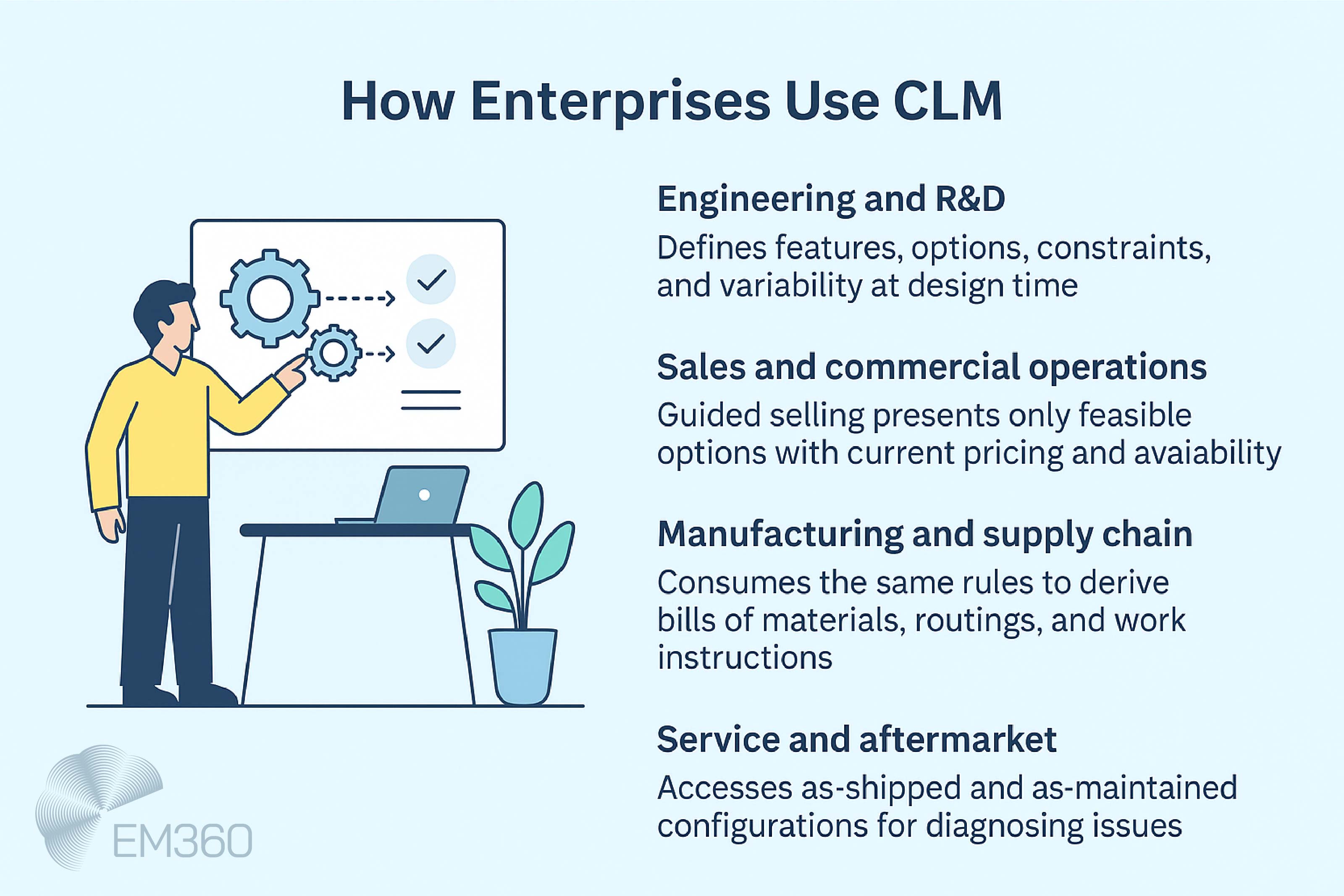

How Enterprises Use the CLM Approach

CLM spans multiple business functions and product types. Before breaking it into sub-areas, ensure the entire section has a shared context: the goal is a consistent configuration truth that different teams can act on in their own systems.

Engineering and R&D

Engineering defines features, options, constraints, and variability at design time. CLM ensures only valid variants reach design release and that released rules are consumable by downstream systems. This avoids engineering work on unmarketable configurations and reduces late rework.

Sales and commercial operations

Inside AIOps Infrastructure Bets

A look at the platforms CIOs trust to correlate telemetry, automate remediation, and hardwire AI into multi-cloud operating models.

Sales teams and partners need fast, accurate quotes for complex offerings. With CLM-backed CPQ, guided selling presents only feasible options with current pricing and availability, cutting cycle times and reducing order errors.

Manufacturing and supply chain

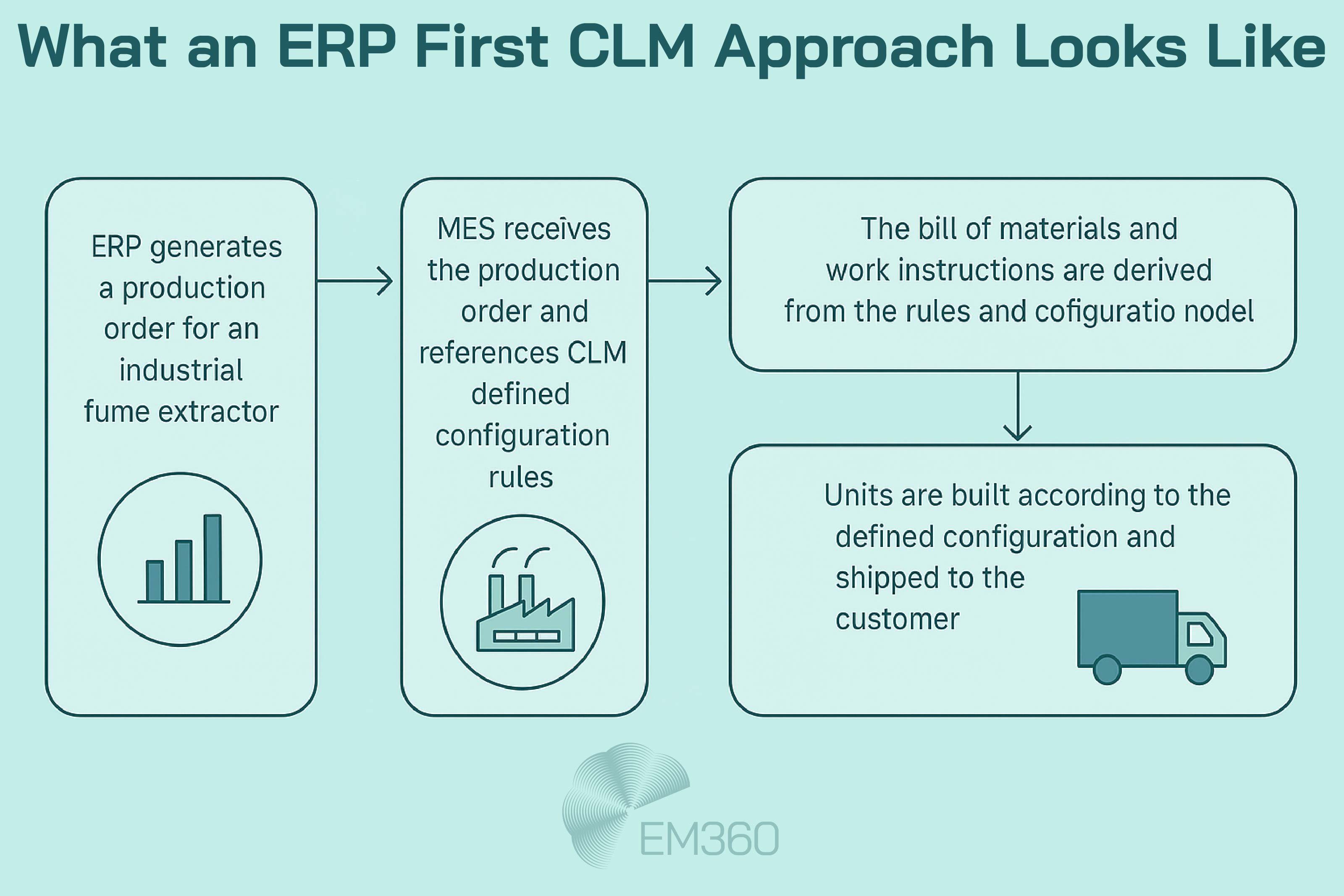

Manufacturing consumes the same rules to derive bills of materials, routings, and work instructions that match what was sold. Alignment with ERP and MES prevents miss-builds and unplanned stoppages.

Service and aftermarket

Service needs the as-shipped and as-maintained configuration to diagnose issues, order correct parts, and plan upgrades. CLM gives field teams reliable configuration histories and valid replacement paths.

IT and network operations

For networks, platforms, and edge devices, configuration management sits inside a broader device lifecycle from planning to decommissioning. CLM principles applied here standardise golden configurations, track deviations, and orchestrate authorised change.

Where CLM Fits In The Architecture

CLM is an approach that acts as a connective layer, not a replacement for PLM, CPQ, or ERP. A practical reference architecture looks like this:

- Model authoring in PLM or a CLM platform defines features, options, and constraints.

- Distribution publishes validated rules to consuming systems: CPQ for quoting, ERP/MES for build, service tools for maintenance.

- Orchestration manages change propagation and approvals across the lifecycle.

- Traceability links configurations and outcomes back to rule and model versions.

Analysts highlight that Configuration Lifecycle Management approaches play a critical role in bringing together the many enterprise systems that often operate in silos. Most organisations rely on a patchwork of platforms — from PLM and ERP to CPQ, MES, service tools, and ITSM — each with its own data model and integration quirks.

Left uncoordinated, these systems create gaps, duplicate effort, and increase the risk of errors. CLM addresses this by acting as a connective layer that establishes a shared configuration backbone.

Instead of every system maintaining its own interpretation of product or infrastructure data, CLM sustains a governed, shared source of truth that can be consumed consistently across the business.

Balancing AI And Human Ops

Explore the cultural, governance, and risk decisions required to let AI augment operations while preserving critical expertise.

The result is not only smoother integration but also enterprise-wide confidence that every decision, from design to service, is based on accurate and traceable configuration information.

Selecting a CLM Approach

There is no single blueprint for what your Configuration Lifecycle Management approach should look like. The right choice depends on your landscape, maturity, and priorities. Most organisations align with one of the patterns below, or adopt a hybrid.

PLM-centric with configuration extensions

Extend your Product Lifecycle Management platform to manage rules and variability, then publish configuration data into ERP, MES, and CPQ. Engineering retains ownership, governance is tight, and standardising on one PLM vendor keeps change controlled.

Specialist CLM backbone

Use a dedicated CLM platform as the configuration authority. It models features, options, and constraints, then distributes validated rules to PLM, ERP, CPQ, and service tools. This suits heterogeneous estates that need a neutral hub and faster iteration.

CPQ-driven with engineering alignment

Let Configure Price Quote take the lead where commercial accuracy is the main pain. Advanced CPQ integrates with PLM so only buildable, supportable combinations are quoted. This is common in partner-heavy sales channels and highly configurable offerings.

ERP or manufacturing-first

Centre the approach in Enterprise Resource Planning or Manufacturing Execution Systems to prioritise operational feasibility. It ensures what is promised can be built and shipped, but it must stay closely synchronised with engineering intent to avoid drift.

IT and infrastructure-centric

Apply CLM principles through Infrastructure as Code, device lifecycle platforms, or IT Service Management. The focus is golden builds, policy and compliance rules, and authorised change, bringing CLM thinking directly into day-to-day IT operations.

Implementation Roadmap for CLM Solutions

Ground the rollout in a clear value stream and work in manageable stages.

1. Inventory and normalise

Catalogue current features, options, constraints, and where rules live. Consolidate terminology and resolve duplications. Identify the authoritative sources for product data, pricing, and availability.

2. Model variability

Why AIOps Now Leads IT Strategy

How AI-driven operations move IT from reactive firefighting to predictive, self-healing services across complex hybrid and cloud environments.

Create a master configuration model with clear semantics. Prioritise high-volume or high-risk product lines and infrastructure domains. Define governance for rule creation, testing, and approval.

3. Integrate the first loop

Choose one closed loop end to end, for example Engineering → CPQ → ERP for a target product family, or Network Design → Deployment → Monitoring for a platform domain. Prove traceability from configuration rules to sold orders, built units, and installed bases.

4. Expand consumers

Publish validated models to additional consumers such as service, supplier portals, and analytics. Establish SLAs for model refresh cadence and change communication.

5. Industrialise governance

Formalise ownership, change boards, test harnesses, and quality gates. Link CLM changes to enterprise change management so decisions are visible and auditable across teams.

Measuring the Value of CLM

Focus on leading indicators that reflect fewer errors, faster cycles, and stronger control.

- Quote accuracy and cycle time in configured deals.

- First-pass yield and miss-build rates in manufacturing.

- Change lead time from engineering decision to field implementation.

- Service right-first-time rate based on accurate as-maintained configurations.

- Audit traceability for safety and regulatory requirements.

Common Pitfalls And How To Avoid Them

Implementing a CLM programme comes with some challenges. Knowing what they are can help organisations make sure to prevent them from occuring.

Treating CLM as a one-off tool rollout

CLM is a cross-functional practice enabled by tools. In other words, it's an approach — not a choice about tools. Without governance, models drift and silos reappear. Establish ownership and operating rhythms from day one.

Divergence between engineering and sales rules

If CPQ carries its own logic, it will eventually contradict engineering. Keep a single model and automate distribution into CPQ so guided selling never proposes invalid combinations.

Ignoring service and installed base

CLM value compounds when it covers as-built and as-maintained configurations. Bring service in early to capture field feedback and improve replacement paths and upgradeability.

Overfitting models to current systems

Model variability independently of today’s implementation quirks. Keep the semantic model clean and use adapters to meet system constraints. This preserves agility as platforms evolve.

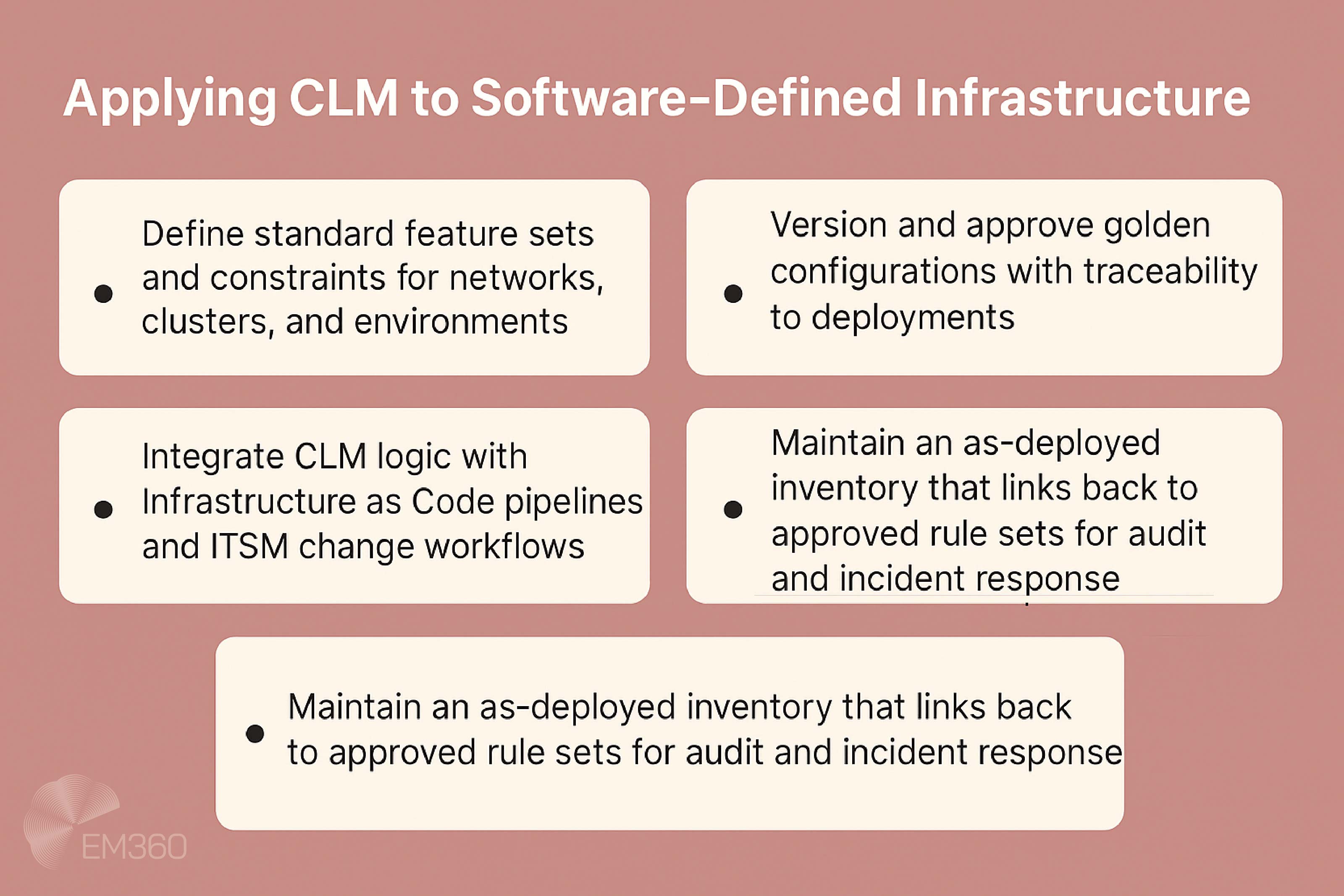

Applying CLM to Software-Defined Infrastructure

While CLM emerged in discrete manufacturing, the approach is powerful for IT estates using SDI strategies:

- Define standard feature sets and constraints for networks, clusters, and environments.

- Version and approve golden configurations with traceability to deployments.

- Integrate CLM logic with Infrastructure as Code pipelines and ITSM change workflows to enforce authorised, testable change.

- Maintain an as-deployed inventory that links back to approved rule sets for audit and incident response.

Vendors frame configuration management as part of device lifecycle management already; CLM brings rule governance and enterprise alignment to the same lifecycle.

Vendor Landscape At A Glance

This market spans multiple categories. Evaluate fit based on how you want to govern configuration truth and where it must flow.

- PLM with configuration depth. PLM suites that harmonise variability and publish to CRM, CPQ, and ERP can anchor a CLM programme when engineering is the primary driver.

- Specialist CLM platforms. Neutral hubs that model rules and distribute to many consumers, often used where estates are heterogeneous or partner-heavy.

- CPQ with engineering alignment. Strong CPQ vendors emphasise PLM integration so what is sold stays buildable and supportable.

Governance Checklist

Before scaling, confirm these non-negotiables:

- A single authoritative configuration model with clear ownership.

- Version control and promotion paths from sandbox to production.

- Automated distribution into CPQ, ERP/MES, service, and analytics.

- Test harnesses for rule changes with regression checks.

- Closed-loop feedback from production and field service.

- Integration patterns that keep PLM, CPQ, ERP, and service in sync.

Final Thoughts: Treat Configuration As A Lifecycle, Not A Task

Configuration is never static. Configuration Lifecycle Management turns that reality into an advantage by aligning every function that touches configuration around a shared, versioned, and governed truth. The payoff is fewer errors, faster decisions, and stronger control across design, sales, build, service, and IT.

Start with one product family or platform domain, close the loop end to end, then expand deliberately. The sooner configuration becomes a lifecycle practice, the sooner complexity stops being a constraint and starts compounding value.

For more insights on how enterprise leaders are tackling challenges like these, explore the latest analysis and expert perspectives at EM360Tech.

Comments ( 0 )