The industrial internet of things companies refers to the companies which use computing network to connect machinery in factories.

Until recently, most machines in factories did not have any computer connectivity. Even to this day, the majority probably do not.

Yes, they have electricity of course, so they’re connected to the power grid, but they often have no computing componentry and no computer connection.

But that’s all changing.

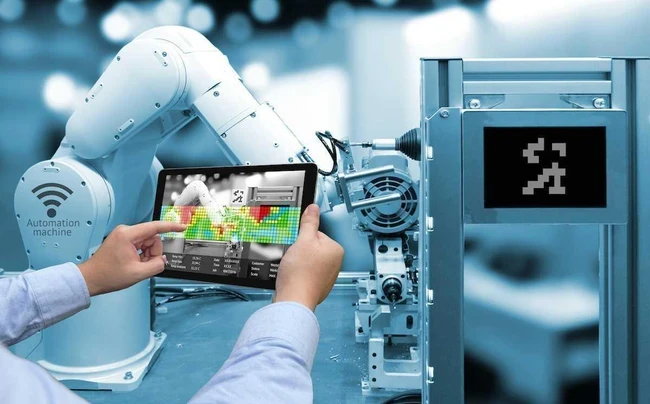

Specially-built sensors and chips are being attached to factory equipment – even to very old equipment – to enable them to connect to a computer network, using Ethernet cables which have different specifications to the ones you might have in your office or home.

The data transfer protocols might be different, too, but without getting too much into the geeky details, the industrial internet of things, or IIoT, is technically different from what might be called the general IoT.

As a result of these differences, the IIoT has developed as a distinct segment of the internet and there are many companies emerging with new and innovative technologies that could make them a fortune.

The reason why this technology is so important to companies is that a typical manufacturer with a large number of machines connected to an IIoT platform can expect to save millions of dollars a year in energy costs alone.

Through an IIoT platform, a factory manager can automate the switching off of machines that are not being used, saving not insignificant sums of money.

They can schedule downtime based on what the sensors are telling them about the condition of the machines. This enables them to avoid disruption to the production process – as unplanned downtime that brings everything to a halt can be extremely expensive.

That’s just two examples of how IIoT platforms are being used, but with artificial intelligence systems being introduced, there will be even more ways to find efficiencies.

There is intense competition developing between the big industrial companies over what could be called the IIoT platform market – which is like a cloud computing service for factories and industrial companies.

General Electric, the gigantic US conglomerate, claims its IIoT platform – Predix – was the world’s first such service when it was launched in 2015 through its business unit GE Digital.

GE also claims Predix to be the largest IIoT platform with more machines, sensors and whatnot connected to it than any other.

Siemens, meanwhile, GE’s European counterpart brags that more than 30 million devices are connected to its IIoT platform, which is called MindSphere.

Both of these IIoT platforms have a large number of apps available through them. For developers, this is becoming another huge market opportunity.

It’s difficult to say which IIoT platform is the largest because most of them don’t share that sort of data. But given that Siemens and GE are two of the largest industrial companies in the world, it’s probably safe to say they are both at or near the top.

The list EM360º has produced below is based on guestimates on how many devices and chips and sensors each IIoT has connected.

However, it’s probably more accurate to think of the 10 companies are just being the largest industrial companies with significant IIoT platforms.

Comments ( 0 )